Stenner Integrator Pump

Couldn't load pickup availability

Why choose a Stenner Pump?

- It eliminates the need for mixing stock solution - simply switch on, set the ratio on the pump and walk away

- The most accurate and reliable system in the range even at low dosages - capable of dosing between 3% solutions down to 1:20000 (0.005%)

- Doses without the need for the delicate (and costly to replace) flow sensors found in some other dosers.

- It has a 3 pinch point pump head for better accuracy and decreased chance of unwanted seepage into the water line

- It has a brushless motor, which requires less maintenance

- It is self priming with no loss of prime due to gaseous solutions

- Quick change pump head making it easy to change rates of use

- Can easily be adapted to work in remote areas such as game release pens and outdoor pig production areas

- Works up to 5.5bar (70psi)

- Comes with 2 different tubes so suitable for a wide range of flow rates.

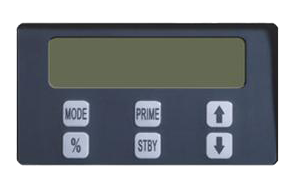

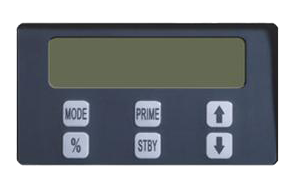

- Easy to program LCD display

- Will dose organic acids

- Solution is not in contact with moving parts and runs through a food grade pump tube

- Almost effortless tube replacement, without tools, with the patented quick release pump head. Click here for a video

- The design allows convenient accessibility.

- Includes a flow indicator for verifying the solution is pumping.

How It Works / Setting Guide

The pump runs at a set time or a set speed according to the mode of operation selected. The control panel displays one of three operating modes, Seconds, Flow Switch and Auxiliary and the percent setting for each. To assist against tampering, two buttons are required for operation and the keypad will automatically lock if it remains idle for one minute. Click here for a general programming video.

SECONDS (dry contact signal) View programming video

In the Seconds mode, the pump can receive a dry (non-voltage) contact signal and will run for a set time in response to receiving the signal. The pump can receive the signal from, for example, a water meter or control valve that sends a dry contact signal. There is a choice of five pump operating time ranges and the maximum time is displayed in the control panel; the run time is adjustable from 10% to 100% in 1% increments.

- 1 SECOND = 0.1 to 1.0

- 5 SECONDS = 0.5 to 5.0

- 10 SECONDS = 1.0 to 10.0

- 20 SECONDS = 2.0 to 20.0

- 60 SECONDS = 6.0 to 60.0

FLOW SWITCH (dry contact signal) View programming video

In the Flow Switch mode, the pump will accept a dry (non-voltage) contact signal from a 2 wire flow switch and will run at the set speed for as long as it receives the dry contact. The pump speed is adjustable from 10% to 100% in 1% increments. The connection is not polarity sensitive (polarity is not an issue when connecting the flow switch wires).

AUXILIARY (12-24 VAC/VDC signal) View programming video

In the Auxiliary mode, the pump can accept a 12-24 VAC/VDC signal and will run at a set speed for as long as it receives the signal. The speed is adjustable from 10% to 100% in 1% increments. The pump can receive the signal from a control valve or another type of control equipment that responds to flow.

Which tube and motor to use?

|

Pump Tube |

Roller Assembly |

Litres per day |

Litres per hour |

Millitres (ml) per hour |

Millitres (ml) per minute |

|

Approximate Maximum Output @ 50/60Hz – 10:1 Turndown |

|||||

|

F |

White |

17.01 |

0.71 |

708.8 |

11.8 |

|

G |

Black |

60.48 |

2.52 |

2,520.0 |

42.0 |

|

H |

Black |

113.40 |

4.73 |

4,725.0 |

78.8 |

Options

Other information

Not suitable for use with Intra Aerosol or Eucalyptus based products.

The Stenner FP pump will require a dry contact water meter to function. Please note that the pump does not come with the water meter, pipe or products shown in the example photograph set ups.

Shipping Policy

Shipping Policy

Shipping charges are calculated dependent on the size and weight of your order. Find out more.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.